光学 MEMS

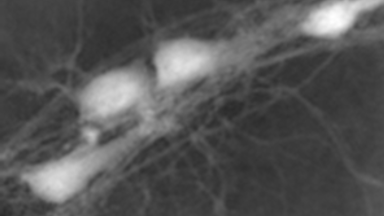

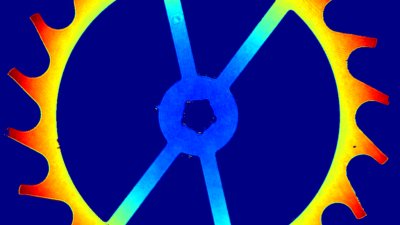

Single-Axis micro-mirror

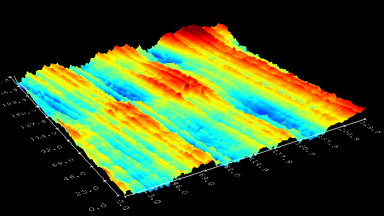

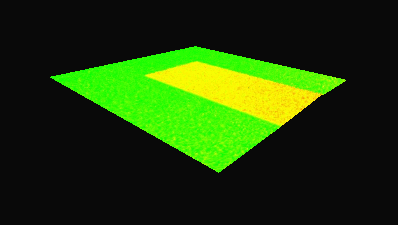

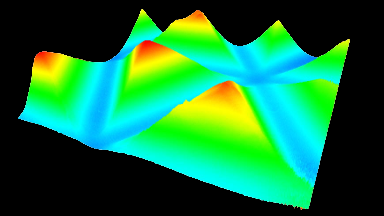

MEMS micro-mirror is a key element of many optical system. Mirror performance are measured thanks to the unique time-sequence of 3d topography allows characterization of :

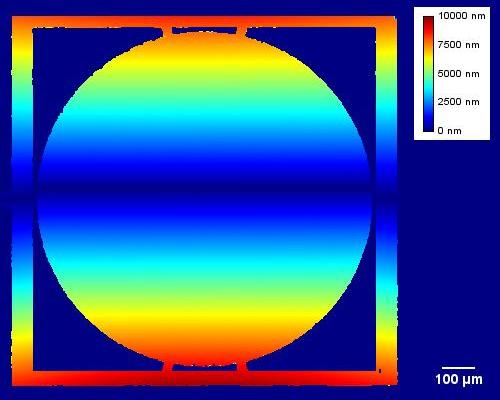

- Surface topography : surface finish, flatness

- Dynamic properties : modal frequency, mode shapes

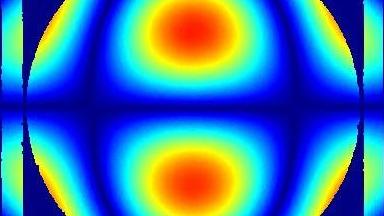

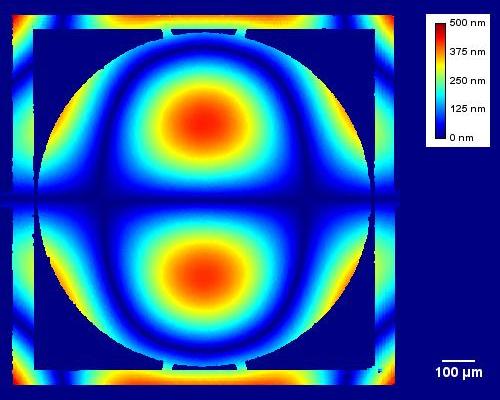

Efficient characterization of mode shapes

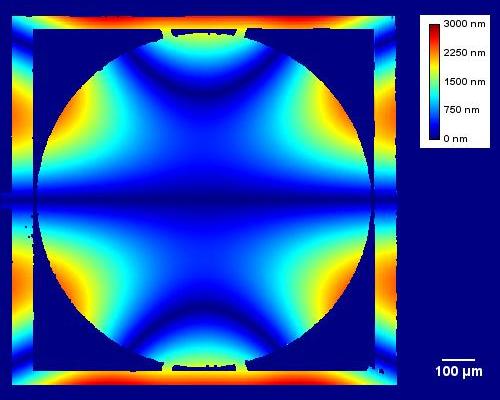

Micro-mirror topography is recorded along the MEMS excitation period for each mode shape. The full-field measurement allow the MEMS designer to characterize :

- Displacement amplitude

- Mirror surface deformation

- Mode shapes

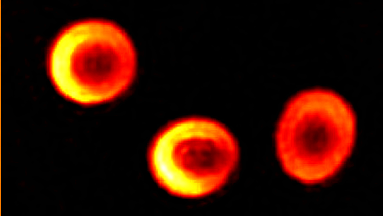

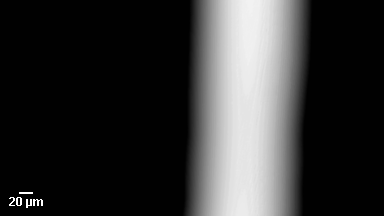

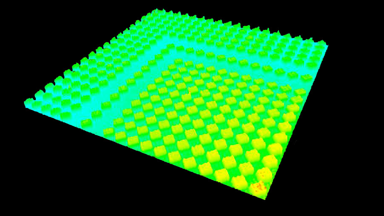

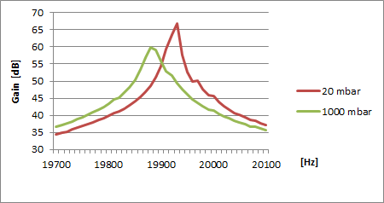

Modal frequency determination in Vacuum

The DHM® unique optical configuration and the large objective collection enables measurement through glass viewport.

Two methods are used to compute modal frequency :

- Bode diagrams by performing a frequency scan

- Fourier Transform by exciting the device with broadband signal

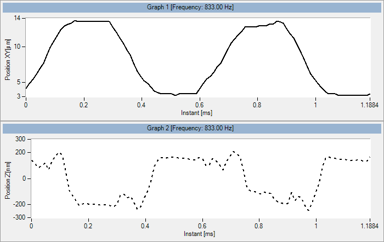

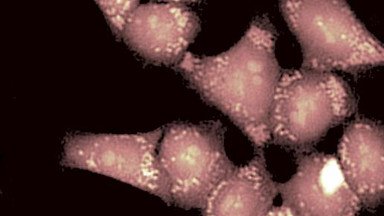

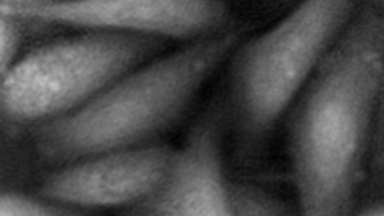

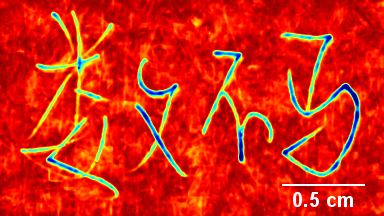

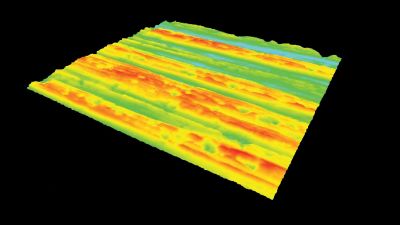

Fast In-plane displacement

Optical shutter is in-plane optical MEMS : silicon parts move in liquids between two glasses. Optimization of in-plane performance requires minimization of out-of-plane displacement.

In- and out-of-plane displacement are recorded simultaneously

The DHM® records time-sequence of 3D topographies up to 25 MHZ, this unique set of data is recorded with a single instrument. It is the sole instrument that measures the evolution of 3D topography along the excitation period. This unique set of data contains also 2 analog and digital electrical inputs.

Recording of in- and out-of-plane is perfectly synchronized, there is no bias introduce by a scanning mechanism or measurement combination.

- In-plane displacement

- Out-of-plane displacement

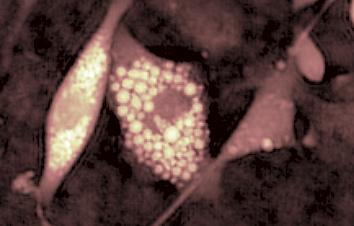

Measurement in liquid

The silicon elements are moving between two glasses in liquid. Compensation of liquid and glass thickness is possible thanks to the DHM® unique optical configuration.

Visit our catalog of objective lens.